The tallest high-altitude demolition machine on the market belongs to Volvo’s high-reach excavator line, reaching up to 118 feet. For example, the Volvo EC300 Straight Boom achieves a maximum reach of 38 feet 7 inches (11.76 meters), as shown below:

| Specification | Value |

| Machine model | Volvo EC300 Straight Boom |

| Maximum digging reach | 38 feet 7 inches (11.76 meters) |

| Product line max reach | Up to 118 feet |

A high-altitude demolition machine features extended horizontal and vertical reach, reinforced boom and arm design, and advanced hydraulics for stability and strength. High reach demolition plays a vital role in building demolition, allowing safe and efficient removal of tall structures in dense urban areas.

Key Takeaways

High-altitude demolition machines can reach heights over 60 meters, allowing safe dismantling of tall buildings from the ground.

These machines feature long, reinforced booms and advanced hydraulics to provide strength, stability, and precise control during demolition.

Specialized attachments like shears, crushers, and grapples increase versatility and efficiency for different demolition tasks.

Operator safety is a top priority, with protective cabs and safety systems shielding workers from falling debris and machine hazards.

Proper site preparation and hazard planning are essential to ensure safe and smooth demolition operations in complex environments.

Leading brands like Runye, Liebherr, Volvo, and Cat offer high-altitude demolition arms with varying reach, weight, and features to fit project needs.

New materials and automation technologies are making demolition machines lighter, stronger, safer, and easier to operate.

Environmental trends push for electric and cleaner machines, reducing emissions and noise while maintaining high performance.

High-Altitude Demolition Machine Overview

What Makes a Machine 'High-Altitude'

A high-altitude demolition machine stands out due to its ability to reach and safely dismantle tall structures. These machines often feature extended booms and reinforced arms that allow them to operate at impressive heights. Most high-altitude demolition machines can reach over 90 feet, with some models extending beyond 100 feet. This reach enables operators to perform high elevation demolition on multi-story buildings and other tall structures.

The design of these machines focuses on stability and control. Engineers equip them with counterweights and advanced hydraulic systems to maintain balance during high-altitude operations. The arm design often includes multiple sections or telescopic features, which provide flexibility and precision. These characteristics ensure that the machine can handle the demands of high-altitude demolition work without compromising safety.

Note: High-altitude demolition machines play a crucial role in urban environments where controlled demolition is necessary to protect nearby buildings and infrastructure.

Key Features

High-altitude demolition machines come with several key features that set them apart from standard demolition equipment:

Extended Reach: The most important feature is the long boom, which allows the machine to access high points on a structure. This capability is essential for high elevation demolition tasks.

Reinforced Structure: Manufacturers build these machines with heavy-duty frames and arms to withstand the stress of demolition operations at great heights.

Advanced Hydraulics: Powerful hydraulic systems provide the force needed for precise and efficient demolition work.

Specialized Attachments: Operators can equip these machines with a variety of tools, such as shears, crushers, and grapples, to handle different demolition operations.

Operator Safety: Cabs often include reinforced glass and protective barriers to shield operators from falling debris during high-altitude demolition.

High-altitude demolition machines have transformed the demolition industry. They allow crews to dismantle tall buildings safely and efficiently, reducing the need for manual labor at dangerous heights. These machines also minimize the impact on surrounding areas, making them ideal for demolition work in crowded city centers. As demolition equipment continues to evolve, high-altitude machines remain essential for tackling the most challenging demolition projects.

Tallest High Reach Demolition Machines

Record-Holding Models

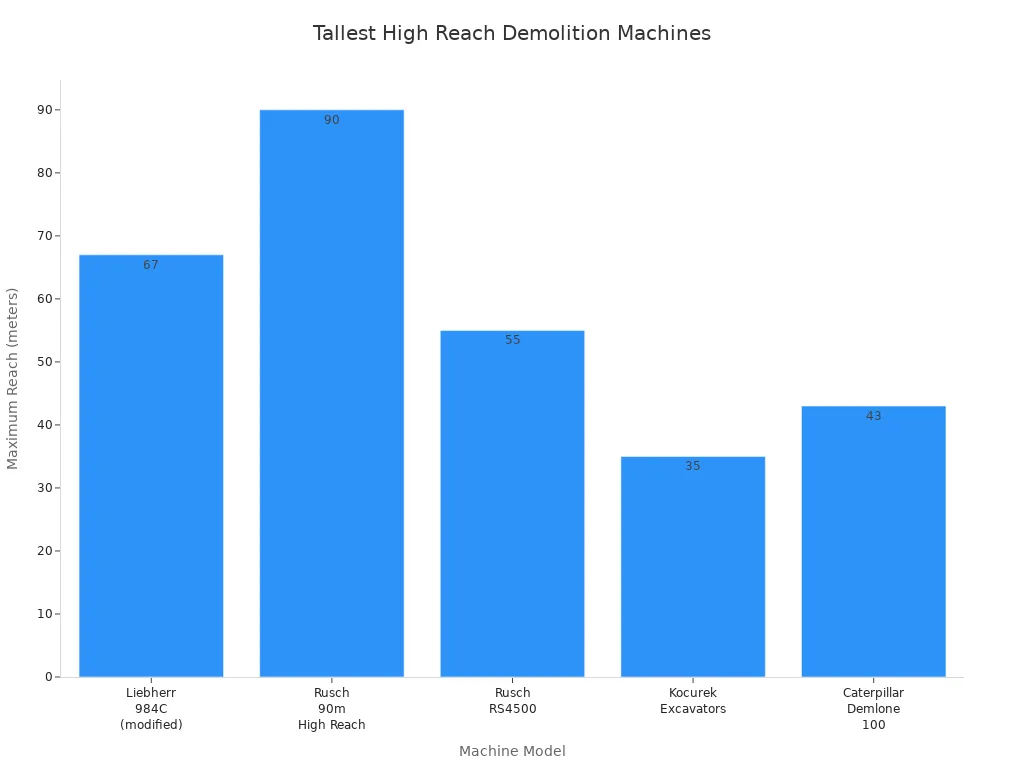

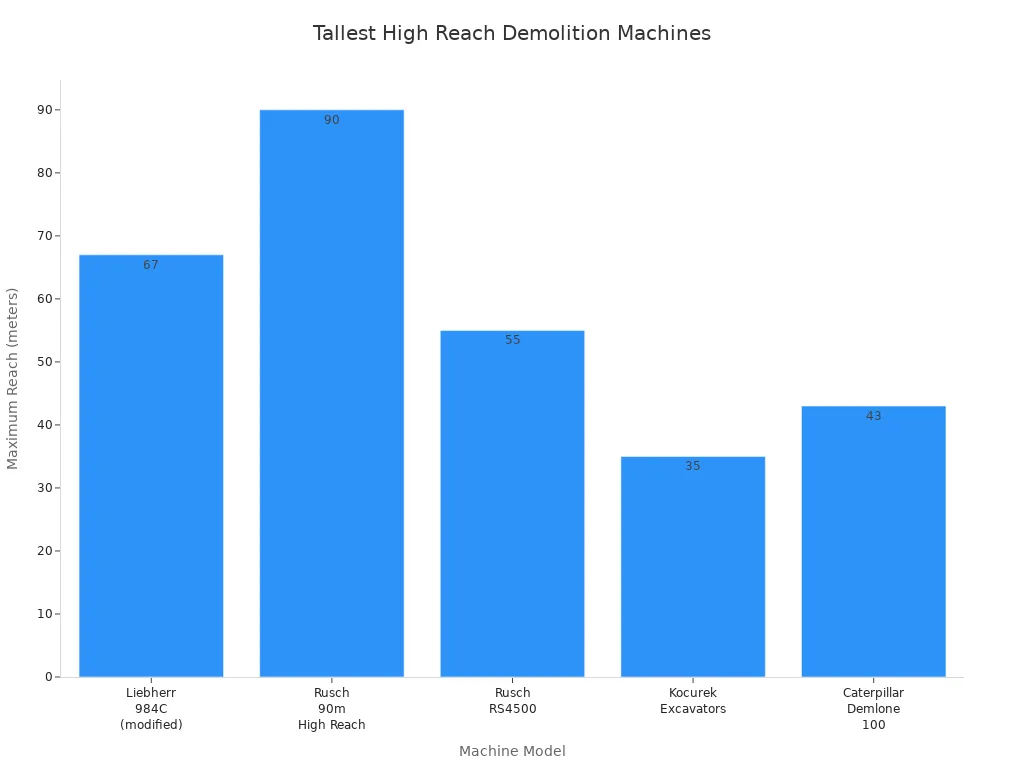

The world of high reach demolition features several record-setting machines engineered for challenging demolition work. These machines stand out for their impressive maximum operating height and their ability to handle heavy attachments at extreme elevations. The Liebherr 984C (modified) currently operates with a maximum reach of 67 meters, making it one of the tallest high reach demolition excavators in active use. The Rusch 90m High Reach once set a record with its 90-meter reach, although it is not currently operational. Other notable models include the Rusch RS4500, Kocurek Excavators, and the Caterpillar Demlone 100, each designed for specialized high-altitude operations.

| Machine Model | Maximum Reach (meters) | Operational Status | Additional Notes |

| Liebherr 984C (modified) | 67 | Currently operational | Used by Technical Demolition Services in Glasgow, UK; can carry 1.5 to 2 tonnes tool weight |

| Rusch 90m High Reach | 90 | Not currently operational (under modification) | Record-breaking height but not working on site |

| Rusch RS4500 | 55 | Operational | Based on Hitachi 870 carrier; carries up to 5 tonnes tool at 55m reach |

| Kocurek Excavators | 35 | Operational | Based on Hitachi EX1200; can carry 8-tonne attachment at max reach |

| Caterpillar Demlone 100 | 43 | Operational | Part of Demlone series; similar working heights offered by Apex series |

Manufacturers continue to push the boundaries of maximum operating height, developing high and ultra-high reach machines that redefine what is possible in building demolition. These machines allow operators to perform demolition work on structures that once required manual dismantling or explosives.

Maximum Reach and Specs

High reach demolition excavators achieve their impressive performance through advanced engineering and robust specifications. The SANY SYC6028, Liebherr R 980, Volvo, and Cat 340 UHD represent some of the most advanced demolition excavators with high reach arms available today. Each model offers unique capabilities for high reach demolition and demolition operations.

| Specification | Value |

| Operating Weight | 200 tonnes |

| Maximum Reach | Up to 60 meters (variants: 21, 26, 36, 55 m) |

| Load Capacity | 15 tonnes (21m & 26m), 7 tonnes (36m), 3 tonnes (55m) |

The Liebherr R 980 Demolition excavator, for example, reaches a maximum operating height of 60 meters and weighs approximately 200 tonnes. It can handle a range of attachments, making it suitable for both high reach demolition and heavy-duty demolition work. The Volvo EC300 Straight Boom, with an arm length of 7 meters and an operating weight of about 70,000 lbs, demonstrates the versatility of high reach work equipment in urban demolition projects.

| Specification | Value |

| Operating Weight | Approximately 70,000 lbs (69,741 - 73,423 lbs) |

| Engine Power | 253 hp at 1,600 rpm |

| Arm Length (Straight Boom) | 7 meters (23 feet) |

These machines deliver reliable performance at maximum operating heights, ensuring safety and efficiency during high-altitude demolition operations. The largest demolition excavator models, such as the Liebherr R 980 and SANY SYC6028, combine strength, reach, and advanced hydraulics to tackle the most demanding demolition projects.

Notable Projects

High reach demolition machines have played a critical role in some of the world’s most challenging demolition projects. Their ability to reach extreme heights and handle heavy attachments makes them indispensable for high reach demolition and demolition operations in urban and industrial environments.

| Project Location | Machine Used | Machine Reach (feet/meters) | Building Height (feet/meters) | Description |

| Y-12 National Security Complex, USA | High-reach excavator | Nearly 180 feet | 80 feet | Demolition of Alpha-2 building, a former Manhattan Project-era enrichment facility, using a 350,000-pound excavator with 180-foot reach. |

| Barcelona, Spain | Liebherr R 980 Demolition excavator | 197 feet (60 meters) | 131 feet (40 meters) | Demolition of reinforced concrete silos (18 circular + 2 square) up to 40 meters high by Hercal using the largest demolition excavator in Iberian Peninsula. |

These projects highlight the importance of maximum operating heights in modern demolition. The Y-12 National Security Complex project in the USA required a high reach excavator with a maximum operating height of nearly 180 feet to safely dismantle an 80-foot-tall building. In Barcelona, the Liebherr R 980 Demolition excavator achieved a maximum operating height of 60 meters to demolish reinforced concrete silos, demonstrating the capabilities of the largest demolition excavator in Europe.

Runye’s Role in High Reach Demolition

Jiangyin Runye Heavy Industry Machinery Co., Ltd. stands as a leading manufacturer of demolition attachments and special application machines. Runye’s product range includes hydraulic shears, eagle beak shears, vehicle dismantling shears, rail shears, orange peel grapples, 3+2 grab forks, clamshell buckets, vibratory hammers, roller compactors, rotating crushers, mechanical crushers, crushing buckets, screening buckets, digging buckets, and customized attachments. These products support high reach demolition excavators and demolition machines worldwide.

Runye specializes in attachments for high reach demolition, enhancing gripping and retention capabilities for efficient demolition operations.

Their shell buckets play a vital role in water conservancy projects, such as river dredging and port desilting.

The company offers serialized attachment products for diverse scenarios, including municipal construction, scrap steel recycling, building demolition, civil construction, material handling, water conservancy, forestry, tunnel construction, and mining.

Runye’s special application machines include long-reach arm excavators, material handlers, demolition excavators, pile driver excavators, vehicle dismantling excavators, lifting cabs, and electric retrofits.

The company maintains strong partnerships with major OEMs like SANY, ZOOMLION, LOVOL, and SDLG, and serves customers in more than 30 countries.

Runye’s commitment to innovation and customization ensures that demolition excavators with high reach arms can operate at maximum operating heights with the right tools for every demolition work scenario. Their expertise supports the ongoing evolution of high reach demolition and the development of the largest demolition excavator models for the global market.

High Altitude Demolition Arm Technology

Arm Design

Engineers design high altitude demolition arms to reach impressive heights while maintaining stability and safety. These arms often extend up to 70 meters or more, allowing demolition crews to tackle tall structures with confidence. The design process focuses on several key principles:

Multi-section arm construction enables extended reach without sacrificing strength.

High-strength, lightweight materials maximize the strength-to-weight ratio, supporting longer arm sections.

Advanced hydraulic systems provide precise control, allowing operators to maneuver the arm smoothly at any height.

Counterweights and optimized load distribution help maintain balance, reducing the risk of tipping.

Computer simulations and real-world testing ensure each high altitude demolition arm meets strict safety standards.

These features allow excavator high altitude demolition arms to operate at maximum operating height, even in challenging environments. The combination of durability, reach, and control makes these arms essential for modern demolition projects.

Multi-Section Arms

Multi-section arms play a crucial role in the performance of high altitude demolition arms. Manufacturers use three-section and telescopic designs to achieve greater reach and flexibility. Each section connects securely, allowing the arm to extend or retract as needed. This modular approach provides several advantages:

Operators can adjust the length of the arm to match the specific requirements of each project.

Telescopic sections offer smooth extension and retraction, improving efficiency during demolition.

The design maintains the structural integrity of the arm, even at maximum operating height.

Enhanced stability features, such as reinforced joints and hydraulic locks, ensure safe operation.

Excavator high altitude demolition arms with multi-section designs can adapt to a wide range of demolition scenarios. This flexibility increases productivity and allows crews to complete complex tasks with fewer machines.

Attachments and Tools

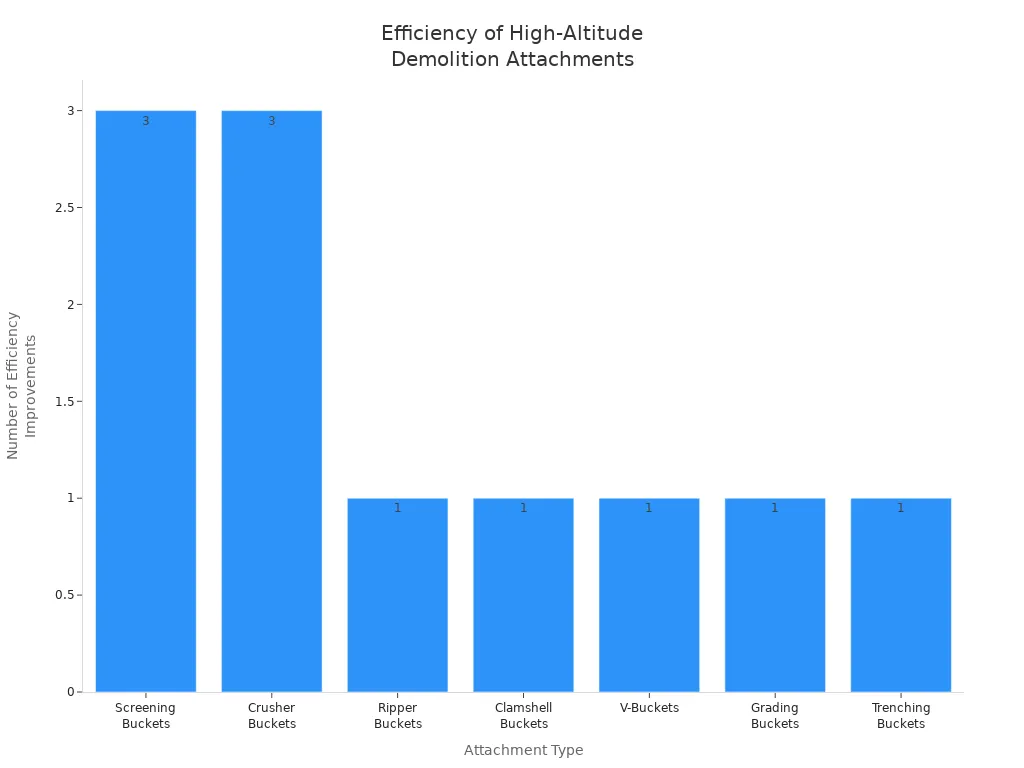

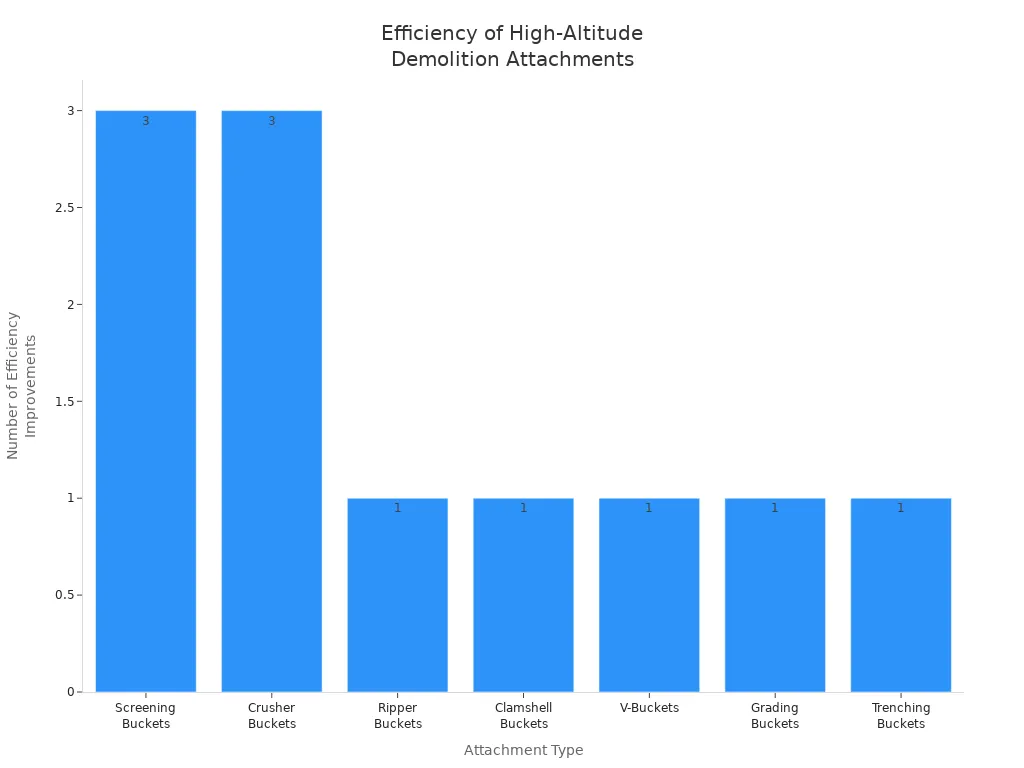

Specialized attachments transform high altitude demolition arms into versatile tools for a variety of tasks. Brands like Runye offer a wide selection of attachments, each designed to improve operational efficiency and safety. The following table highlights some common attachments and their benefits:

| Attachment Type | Description and Functionality | Operational Efficiency Improvement |

| Screening Buckets | Separate waste and rubble on-site, enabling material reuse | Reduces disposal costs, minimizes waste, and decreases need for multiple machines |

| Crusher Buckets | Crush hard materials like concrete and stone directly on-site | Saves transportation costs, reduces landfill waste, and enables fast material processing |

| Ripper Buckets | Break up hard, compacted ground | Facilitates ground penetration and preparation for demolition tasks |

| Clamshell Buckets | Lift and carry bulk materials | Enhances material handling efficiency |

| V-Buckets | Create ditches with specific angles | Improves precision in trenching and grading tasks |

| Grading Buckets | Finish and level surfaces | Provides smooth surface preparation |

| Trenching Buckets | Dig narrow, deep trenches | Enables precise trench excavation |

Runye’s attachments, such as hydraulic shears, orange peel grabs, and clamshell buckets, allow high altitude demolition arms to handle material processing, sorting, and heavy-duty demolition. These tools enable machines to work efficiently at maximum operating height, reducing the need for additional equipment and streamlining the demolition process. The right combination of excavator high altitude demolition arms and specialized attachments ensures safe, precise, and productive demolition operations.

High Reach Demolition Safety

Operator Protection

Operator safety stands as a top priority in high-altitude demolition. Modern machines include advanced protective features that shield operators from hazards such as falling debris, rollovers, and tip-overs. The following table outlines the most common operator protection systems and their purposes:

| Protection Feature | Purpose and Hazards Addressed | Relevant ISO Standards | Additional Notes |

| Roll Over Protective Structure (ROPS) | Protects operator in case of machine rollovers | ISO 8082-1, ISO 8082-2, ISO 3471, ISO 12117-2 | Applies to construction and demolition machines; certified by permanent label |

| Falling Object Protective Structure (FOPS) | Shields against falling debris such as rocks or heavy objects | ISO 3449 (Level 1 and Level 2) | Level 2 required for demolition; protects against large falling objects |

| Tip-Over Protective Structure (TOPS) | Ensures operator safety during machine tip-overs | ISO 12117-1 | Applies to compact excavators; tested for static load and tip-over conditions |

| Operator Protective Structure (OPS) | Minimizes injury from hazards like snapping winch lines or sharp objects | ISO 8084 | Used in crawlers and skidders; meets OSHA and regional safety standards |

These features, combined with reinforced cabs and clear visibility, help operators manage the high-risk operation of tall building demolition.

Machine Stability

Maintaining machine stability is essential for safe demolition at maximum reach. Several factors contribute to stability during high-altitude work:

Advanced hydraulic systems provide precise control of arm movements, reducing the risk of sudden shifts.

The base machine’s weight and counterbalance capacity support the structure during extended reach.

Strong structural design and high-quality materials allow the demolition arm to handle heavy loads.

The weight of attachments affects stability; heavier tools may lower the safe operating height.

Integrated safety systems, such as automatic cut-off mechanisms, prevent overextension or overloading.

Operators monitor environmental conditions, including wind speed and direction, to ensure safe operation.

These elements work together to keep the machine steady and secure, even when working at great heights.

Site Preparation

Proper site preparation forms the foundation of all safety measures in high reach demolition. Crews follow a series of steps to ensure a safe and efficient work environment:

Conduct a thorough engineering survey to assess the building’s structure and identify risks of collapse.

Identify and document hazardous materials, such as asbestos or lead-based paint.

Develop a hazards plan that addresses risks like fires, explosions, and structural failures.

Implement protection for the public, including secure barriers and pedestrian walkways.

Map and safeguard all utilities, both overhead and underground.

Prepare protocols for handling tanks or hazardous residues.

Coordinate with all involved parties, including subcontractors, to ensure smooth operations.

Equip workers with personal protective equipment tailored to identified hazards.

Maintain clear communication and provide training to uphold safety standards throughout the project.

Tip: Careful planning and communication help crews address challenges such as tight urban spaces, hazardous materials, and complex logistics.

By following these steps, demolition teams create a safer environment for both workers and the public, reducing the risk of accidents and ensuring compliance with regulations.

High Altitude Demolition Arms Comparison

Leading Brands

Several brands lead the global market for high altitude demolition arms. Runye, SANY, Liebherr, Volvo, and Cat have each developed specialized solutions for demanding demolition projects. Runye stands out for its innovative attachments and custom high altitude demolition arm designs, serving a wide range of industries. SANY and Liebherr produce some of the tallest demolition variants, often used in large-scale urban projects. Volvo and Cat focus on reliability and operator safety, offering high reach work equipment that meets strict international standards.

Note: Leading brands often collaborate with attachment specialists like Runye to enhance the versatility and efficiency of their machines.

Performance Differences

High altitude demolition arms differ in reach, weight, and technology. The following table compares key specifications among top models:

| Brand/Model | Maximum Operating Height | Operating Weight | Key Features | Typical Applications |

| Runye (Custom Arms) | Up to 60 meters | 23–200 tons | Multi-section arms, bespoke attachments | Building demolition, recycling |

| SANY SYC6028 | 60 meters | 200 tons | Telescopic boom, advanced hydraulics | High-rise demolition |

| Liebherr R 980 | 60 meters | 190–200 tons | Modular arm system, FOPS/FOGS cab | Industrial demolition |

| Volvo EC300 UHD | 32 meters | 70 tons | Straight boom, reinforced cab | Urban demolition |

| Cat 340 UHD | 22 meters | 50–60 tons | Quick-change boom, operator safety features | Mid-rise demolition |

Runye’s high altitude demolition arms offer flexibility through custom engineering and a wide range of attachments. SANY and Liebherr focus on maximum operating height and robust construction. Volvo and Cat emphasize ease of use and safety, making them popular choices for city projects.

Advantages and Limitations

High altitude demolition arms provide significant benefits for demolition crews. They reach heights above 20 meters, with some models extending beyond 60 meters. This capability allows operators to dismantle tall structures safely from the ground. The broad operating weight range, from 23 to 200 tons, supports robust demolition tasks and enables the use of various attachments.

Versatility remains a key advantage. Multi-piece, pin-jointed, or telescopic work equipment allows machines to carry specialized tools for different demolition tasks. However, these machines require careful site setup, especially when working at maximum operating height. Operators must consider ground conditions and potential hazards before starting work.

| Aspect | Advantages | Limitations |

| Reach | Operating height above 20 meters, some over 60 meters | Requires careful site setup and hazard assessment |

| Weight | Wide range (23–200 tons) for robust demolition | Attachment weight restrictions based on installed work equipment |

| Versatility | Multi-section arms and custom attachments for diverse tasks | Not suitable for lifting like cranes; safety rules limit arm movement with lodged materials |

Machines must include safety features such as FOPS and FOGS cabs to protect operators from falling debris. While high altitude demolition arms excel in reach and versatility, operational safety and proper planning remain essential for every project.

Future of High-Altitude Demolition Machine

New Materials

Manufacturers continue to seek stronger and lighter materials for high-altitude demolition machines. High-strength steels such as Q355B, NM400/450/500, and Hardox grades 450/500/550 have become standard in the construction of long reach booms and arms. These steels withstand tough site conditions and provide the durability needed for demanding demolition tasks. By using advanced high-strength steels, engineers can optimize the weight of machinery parts without sacrificing strength. This approach allows machines to reach greater heights while maintaining stability and safety. As research progresses, the industry expects to see further improvements in material science, which may lead to even lighter and more resilient components.

Automation

Automation is transforming the demolition industry. High-altitude demolition machines now feature advanced control systems that assist operators with precision tasks. Remote operation technology allows crews to control machines from a safe distance, reducing exposure to hazards. Some machines use sensors and cameras to provide real-time feedback, helping operators make better decisions during complex demolition projects. Artificial intelligence and machine learning are beginning to play a role in optimizing machine performance. These technologies can analyze data from previous jobs and suggest the most efficient demolition strategies. As automation advances, high-altitude demolition machines will become safer, more efficient, and easier to operate.

Environmental Trends

Environmental concerns shape the future of high-altitude demolition machines. Several trends influence design and operation:

Electric motors deliver consistent power, regardless of altitude or temperature, which ensures reliable performance in various conditions.

Stricter environmental regulations and emissions standards drive the adoption of cleaner, electric technologies to reduce emissions and comply with laws.

Integration with renewable energy sources, such as solar and wind, supports sustainability and energy resilience on construction sites.

Electric equipment provides zero emissions and quieter operation, which benefits confined or environmentally sensitive areas.

Advances in battery technology and energy storage enable longer operation times and better energy management.

The shift toward electrification, sustainability, and automation is reshaping the demolition industry. Manufacturers now focus on reducing environmental impact while maintaining high performance. These changes help companies meet regulatory requirements and support a cleaner, quieter, and more efficient worksite.

The Liebherr 984C (modified) currently holds the record for highest reach among high-altitude demolition machines, achieving up to 67 meters. Engineering advancements and strict safety standards drive the evolution of these machines, ensuring operators can dismantle tall structures with precision and protection. Ongoing innovations continue to shape the industry:

High-reach excavators allow controlled, piece-by-piece demolition.

Specialized attachments like shears and crushers increase versatility.

Improved safety features enable work from a safe distance.

Reduced dust and debris help protect surrounding areas.

Precision takedown minimizes risk to nearby buildings.

| Manufacturer | Key Innovations and Features |

| Volvo | Modular booms, real-time stability alerts, smart controls, improved fuel efficiency |

| SENNEBOGEN | Telescopic undercarriage, rapid attachment changes, advanced safety systems |

| Komatsu | Quick boom change, increased reach, robust guarding |

When evaluating demolition solutions, readers should weigh both technological advancements and safety measures to ensure efficient and secure project outcomes.

FAQ

What is a high-altitude demolition machine?

A high-altitude demolition machine uses an extended boom or arm to reach and dismantle tall structures. These machines operate at heights above 20 meters, making them essential for safe and efficient demolition of multi-story buildings.

How do operators stay safe during high-reach demolition?

Operators rely on reinforced cabs, advanced safety systems, and protective structures like ROPS and FOPS. They also follow strict safety protocols and use personal protective equipment to minimize risks from falling debris and machine instability.

Which attachments work best for high-altitude demolition?

Attachments such as hydraulic shears, crushers, orange peel grabs, and clamshell buckets provide versatility. Brands like Runye design specialized tools to handle concrete, steel, and debris at extreme heights, improving efficiency and safety.

What is the tallest high-reach demolition machine in use?

The Liebherr 984C (modified) currently holds the record, reaching up to 67 meters. This machine operates in demanding demolition projects and can handle heavy attachments at maximum height.

Why do demolition companies choose custom arms and attachments?

Custom arms and attachments allow companies to match equipment to specific project needs. This flexibility increases productivity, improves safety, and ensures machines can handle unique demolition challenges.

How does automation improve high-altitude demolition?

Automation enables remote operation, real-time monitoring, and precision control. These features reduce operator exposure to hazards and increase efficiency during complex demolition tasks.

What trends shape the future of high-altitude demolition machines?

| Trend | Impact |

| New materials | Lighter, stronger arms for greater reach |

| Automation | Safer, more precise operations |

| Electrification | Lower emissions and quieter job sites |

Manufacturers continue to innovate, focusing on sustainability and advanced technology.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori