An automotive machine refers to specialized equipment designed to handle tasks in the automotive industry, such as dismantling vehicles for recycling. A Car Dismantling Machine breaks down old cars, allowing recyclers to recover valuable parts and materials. These machines play a crucial role in modern vehicle recycling by increasing automation and improving safety.

Automation boosts efficiency, reduces labor costs, and raises processing volumes.

Advanced machines enhance precision and help recover complex components.

Data-driven systems streamline operations and support environmental goals.

The Runye Car Dismantling Machine stands out as a leading example, offering advanced tools for efficient and safe vehicle dismantling.

Key Takeaways

Car dismantling machines break down old vehicles to recover valuable parts and materials efficiently.

These machines improve safety by using enclosed tools and automated fluid removal to protect workers and the environment.

Advanced machines like the Runye model increase recycling speed, reduce labor costs, and boost material recovery rates.

Key functions include disassembly, fluid draining, crushing, sorting, and compacting materials for easier handling and transport.

Automated systems and attachments make machines versatile, allowing recyclers to handle different vehicle parts and materials.

Using car dismantling machines supports environmental goals by reducing waste, preventing pollution, and conserving resources.

Future trends focus on automation, AI, and digital integration to enhance efficiency, safety, and predictive maintenance.

Investing in modern dismantling machines helps recycling businesses increase profits through higher recovery and faster processing.

Car Dismantling Machine Overview

Definition

A car dismantling machine is a specialized piece of equipment used in the automotive recycling industry. This machine helps break down old or damaged vehicles into smaller parts. Operators use powerful rotating hammers to smash the car into small pieces. After the car is broken apart, the machine sorts the mixture to separate different materials. These materials include steel, iron, aluminum, copper, plastics, glass, and rubber. Advanced technologies, such as magnets, eddy current separators, and flotation tanks, help make the sorting process more accurate and efficient.

Car dismantling machines make it possible to recover valuable resources from vehicles that can no longer be used on the road.

Main Purpose

The main purpose of a car dismantling machine is to streamline the recycling process for vehicles. By breaking down cars quickly and safely, these machines help recyclers recover useful materials and parts. This process reduces waste and supports environmental sustainability. The Runye Car Dismantling Machine stands out as a leading example in the industry. It uses advanced cutting tools and safety features to improve both speed and precision. With this machine, recycling businesses can increase productivity and reduce manual labor. The organized dismantling process also helps recyclers get more valuable materials from each vehicle.

The use of machines like the Runye Car Dismantling Machine has become essential for modern automotive recycling operations.

Key Functions

Disassembly

Car dismantling machines perform a series of important steps to break down vehicles for recycling. The process begins with draining waste oils and other fluids from the car. This step prevents environmental pollution and prepares the vehicle for safe handling. Workers then remove reusable parts such as bumpers, doors, and engines. These parts can be sold for second-hand use, which supports the reuse of valuable components.

After removing the main parts, the machine flattens or presses the remaining vehicle body into a compact cube. This makes the car easier to handle and transport. The pressed cube then goes through a shredder, which breaks it into smaller pieces. The machine sorts these pieces by separating scrap steel from non-ferrous metals like aluminum and copper. Finally, advanced systems use airflow and sensors to separate shredder residue, such as resins, urethane, and glass, into recyclable materials.

Each step in the disassembly process helps maximize the recovery of valuable resources and reduces waste.

Material Recovery

Material recovery stands at the core of automotive recycling. Car dismantling machines recover a wide range of metals and materials from end-of-life vehicles. Steel, iron, aluminum, and copper are the most commonly recovered materials. The average metal recovery rate reaches about 82%, which highlights the efficiency of modern recycling operations. The United States, for example, generates about 1,200 kilotons of waste steel sheet from vehicles each year.

| Material | Description/Notes | Average Recovery Rate |

| Steel | Waste steel sheet from automotive bodies | ~82% |

| Iron | Commonly recovered metal | Included in overall metal recovery |

| Aluminum | Recovered from end-of-life vehicles | Included in overall metal recovery |

| Copper | Recovered from end-of-life vehicles | Included in overall metal recovery |

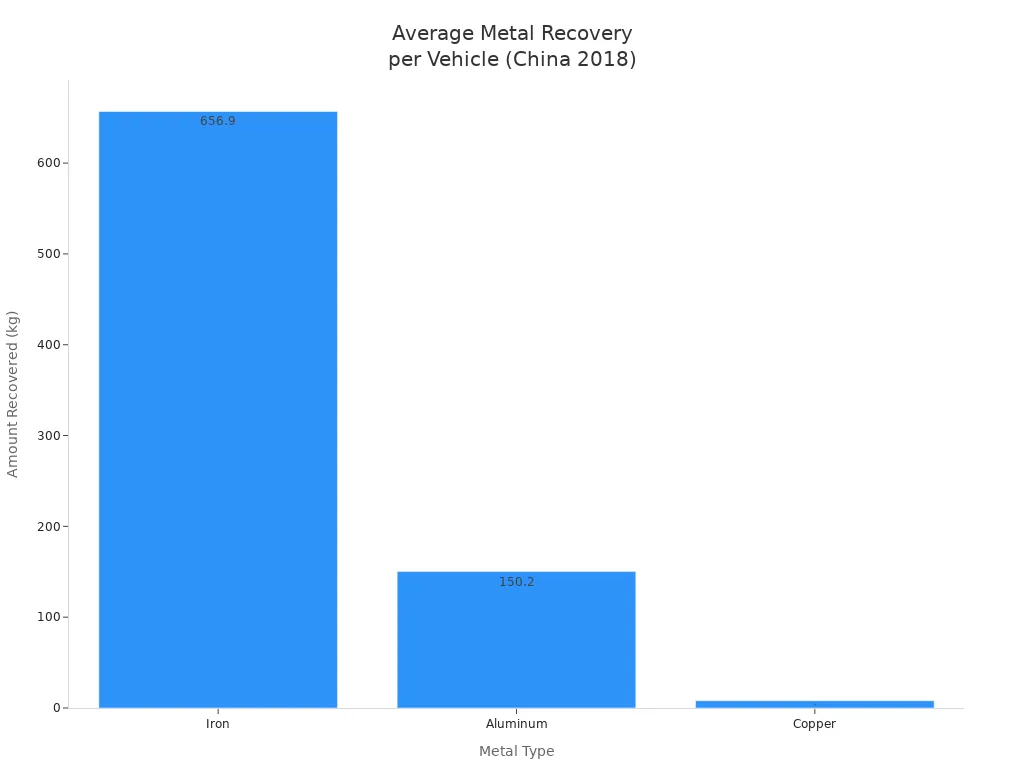

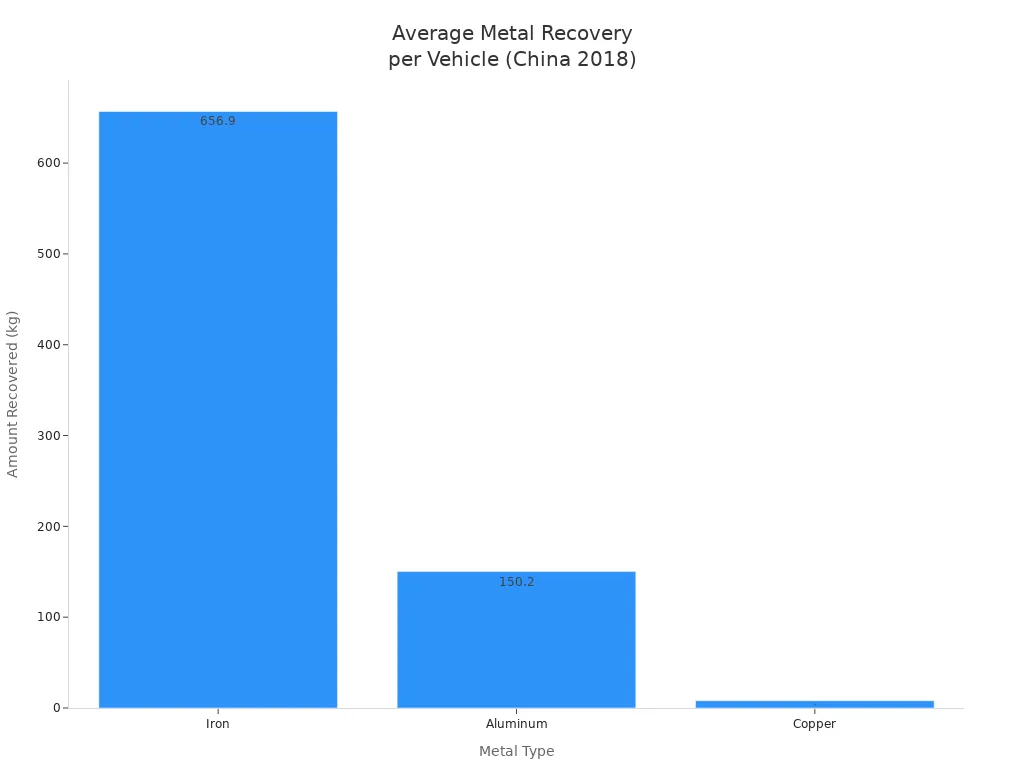

In China, each vehicle yields about 656.9 kg of iron, 150.2 kg of aluminum, and 7.9 kg of copper. These numbers show the significant impact of recycling on resource conservation.

The European Union sets strict standards for vehicle recycling. It requires a minimum reuse and recovery rate of 95% by weight per vehicle, with at least 85% coming from recycling. Many countries, such as Lithuania, have achieved or even surpassed these targets.

Safety Features

Safety remains a top priority in the design and operation of car dismantling machines. Modern machines include features that protect workers and the environment. Enclosed cutting tools and shields prevent accidental contact with moving parts. Automated fluid draining systems reduce the risk of spills and exposure to hazardous substances. Emergency stop buttons and clear control panels allow operators to respond quickly to any issues.

The Runye Car Dismantling Machine, for example, uses advanced safety systems to ensure smooth and secure operation. These features help recycling businesses maintain a safe workplace while meeting environmental regulations.

Types of Car Dismantling Machines

Car dismantling facilities use a range of machines to process vehicles efficiently. Each type of machine serves a specific function in the recycling process. The right equipment helps recyclers recover valuable materials, improve safety, and meet environmental standards.

Shears

Shears play a vital role in the dismantling process. These machines use powerful hydraulic blades to cut through metal parts of vehicles. Operators use shears to slice frames, axles, and other large components into smaller pieces. This step makes it easier to handle and transport the materials. Shears can cut through thick steel with precision. Many recycling centers rely on brands like Kobelco and Powerhand for their robust shearing equipment. The Runye Car Dismantling Machine also features advanced shearing tools, allowing for quick and safe separation of metal parts.

Shears help recyclers reduce the size of vehicle components, making the next steps in the recycling process more manageable.

Crushers

Crushers flatten and compress entire vehicles or large sections of cars. These machines use heavy plates or rollers to crush the car body into a compact shape. Crushing reduces the volume of scrap, which saves space during storage and transport. Many facilities use crushers before sending materials to shredders or balers. Gensco and other leading brands offer crushers with high force and reliable performance. The Runye Car Dismantling Machine integrates crushing functions to streamline the workflow and boost productivity.

Crushers also improve safety by stabilizing the vehicle before further processing. Workers can handle compacted cars more easily, reducing the risk of accidents.

Balers

Balers compress recovered materials, such as metals, into dense bales. This process makes storage and shipping more efficient. Balers handle a variety of materials, including steel, aluminum, and copper. The compact bales take up less space and are easier to load onto trucks or into containers.

The following table shows the typical cost range for baling machines and other equipment used in car dismantling:

| Machine Type | Description | Cost Range (USD) |

| Baling Machines | Compress recovered materials like metals into bales for easier storage and transport. | $15,000 - $100,000 |

| Separators | Machines that separate materials: magnetic for metals, air classifiers for plastics, eddy current for non-ferrous metals. | $10,000 - $50,000 |

| Dust Collection Systems | Systems essential for maintaining air quality and regulatory compliance. | $10,000 - $50,000 |

| Storage and Handling Equipment | Includes containers, racks, and pallets for storing recyclable materials. | $5,000 - $20,000 |

Balers from brands like Powerhand and Runye offer strong compression and easy operation. Many modern balers include safety features and automated controls. These machines help recyclers prepare materials for sale or further processing.

Efficient baling supports a smooth recycling operation and helps businesses meet industry standards.

Fluid Drainers

Fluid drainers remove hazardous liquids from vehicles before dismantling. These machines play a key role in protecting the environment and worker safety. Cars contain many fluids, such as engine oil, coolant, brake fluid, transmission fluid, and fuel. If not handled properly, these liquids can cause pollution or harm workers.

Operators use fluid drainers to extract all fluids quickly and safely. The machines connect to the vehicle’s fluid reservoirs using hoses and suction pumps. Some models use vacuum systems to speed up the process. Fluid drainers collect the liquids in sealed containers for safe disposal or recycling.

Proper fluid removal prevents spills and reduces fire risks in recycling facilities.

Many brands offer fluid draining equipment. Gensco and Powerhand produce reliable fluid drainers for automotive recycling. The Runye Car Dismantling Machine includes advanced fluid draining systems. These systems automate the extraction process and minimize manual handling. Operators can drain multiple fluids at once, which saves time and improves efficiency.

Key features of modern fluid drainers include:

Fluid drainers help recycling centers meet environmental regulations. They also protect workers from exposure to toxic substances. Efficient fluid removal supports a cleaner and safer dismantling process.

Attachments

Attachments expand the capabilities of car dismantling machines. These tools connect to the main machine and perform specialized tasks. Operators can switch attachments to handle different parts of the vehicle.

Common attachments include:

Grapples: Grab and lift large vehicle parts

Magnets: Pick up ferrous metals like steel

Cutting torches: Slice through thick metal sections

Rotating claws: Twist and pull apart components

Attachments make car dismantling machines more versatile and adaptable.

Industry leaders such as Kobelco and Powerhand offer a wide range of attachments. These tools help recyclers process vehicles more efficiently. The Runye Car Dismantling Machine supports various attachments. Its design allows for quick changes between tools, which reduces downtime.

The table below shows examples of common attachments and their uses:

| Attachment | Main Use | Example Brand |

| Grapple | Lifting and moving parts | Powerhand |

| Magnet | Collecting ferrous metals | Gensco |

| Cutting Torch | Cutting through metal | Kobelco |

| Rotating Claw | Disassembling components | Runye |

Attachments improve productivity and safety. They let operators handle many tasks with one machine. This flexibility helps recycling businesses adapt to different vehicles and materials. By using the right attachments, recyclers can recover more valuable materials and reduce manual labor.

How Car Dismantling Machines Work

Preparation

Preparation forms the foundation of safe and efficient vehicle dismantling. Operators begin by disconnecting all power sources from the vehicle. They visually confirm that no residual energy remains. This step prevents accidental electrical discharge. Workers then remove the spark plug lead on internal combustion engines to avoid unintentional ignition. They check for any energy storage devices, such as batteries or capacitors, and discharge them safely.

Next, operators remove hazardous fluids like fuel, oil, and coolant. They follow strict de-pollution procedures to protect both workers and the environment. Precautions against sparks, sharp blades, and flammable chemicals help prevent accidents. Fire extinguishers remain close by as a safety measure. Teams follow standardized dismantling procedures to ensure every step meets safety and efficiency standards.

Proper preparation reduces risks and sets the stage for a smooth dismantling process.

Fluid Removal

Fluid removal is a critical step in the car recycling process. Modern car dismantling machines use advanced fluid recovery systems to extract hazardous liquids from vehicles. These systems often tilt and roll the vehicle, allowing for maximum fluid drainage. For example, patented technologies can recover up to 50% more fluid than traditional methods. Pneumatic pumping systems provide powerful suction, speeding up the extraction process.

Operators use these machines to remove engine oil, coolant, brake fluid, transmission fluid, and fuel. The fluids collect in sealed containers for safe disposal or recycling. Some systems include fluid separators, which allow for the reuse or sale of recovered fluids. This step not only protects the environment but also ensures compliance with safety and environmental regulations.

Efficient fluid removal prevents spills, reduces fire risks, and supports responsible recycling.

Component Separation

Component separation involves removing valuable and reusable parts from the vehicle. Workers systematically disassemble the car to separate reusable parts, scrap metals, and hazardous materials. They drain and dispose of hazardous fluids and batteries to prevent contamination. Next, they remove valuable metals such as steel, aluminum, and copper for recycling.

Reusable parts like engines, transmissions, and wheels are taken out for resale or refurbishment. Operators also recover electronics, seats, and door systems. The remaining vehicle structure goes through shredding and mechanical separation. Magnetic systems extract ferrous metals, while eddy current and density-based sorting recover non-ferrous metals. Plastics, textiles, and other materials are sorted for recycling or energy recovery.

This multi-stage process reduces landfill waste and supports sustainable recycling practices. The Car Dismantling Machine streamlines these steps, making the separation of valuable components faster and safer.

Systematic component separation maximizes resource recovery and minimizes environmental impact.

Crushing and Compaction

Crushing and compaction form a critical stage in the car dismantling process. After workers remove valuable parts and hazardous fluids, the remaining car body needs to be reduced in size. This step makes handling, storage, and transportation much easier for recycling centers.

Car dismantling machines use powerful hydraulic presses or rollers to crush vehicles. The machine flattens the car body, breaking it down into a compact shape. This process reduces the volume of the vehicle by up to 80%. Smaller, denser pieces take up less space in storage yards and shipping containers.

Crushing and compaction help recyclers save space, lower transportation costs, and prepare materials for further processing.

Many facilities use machines like the Runye Car Dismantling Machine for this step. Runye’s equipment features advanced hydraulic systems that deliver strong, even pressure. Operators can control the crushing force and speed, which ensures consistent results for different vehicle types. The machine’s design also keeps workers safe by enclosing moving parts and providing emergency stop controls.

Other leading brands, such as Gensco and Powerhand, offer similar crushing technology. These machines often include automated controls and sensors. Automation allows operators to process more vehicles in less time. Sensors monitor the crushing process and stop the machine if they detect a problem. This feature protects both the equipment and the workers.

The compaction process often follows crushing. Machines compress the crushed car body into dense cubes or rectangular bales. This step uses a baler, which squeezes the metal tightly together. Compacted bales are easier to stack and transport. They also meet the requirements of steel mills and foundries that buy recycled metal.

Here is a simple overview of the crushing and compaction process:

Place the stripped car body into the crushing chamber.

Activate the hydraulic press or rollers to flatten the vehicle.

Remove the crushed car from the chamber.

Load the crushed body into a baler for further compaction.

Compress the material into a dense bale for shipping.

Machines like the Runye Car Dismantling Machine combine crushing and compaction functions. This integration streamlines the workflow and boosts productivity. Operators can process more vehicles each day, which increases the recycling center’s output.

Efficient crushing and compaction support a cleaner, safer, and more profitable recycling operation. These steps also help recyclers meet environmental and industry standards.

Benefits

Efficiency

Modern vehicle recycling facilities rely on advanced machines to boost efficiency. These machines help workers process vehicles faster and with less effort. Shear attachments allow precise cutting and dismantling, which speeds up the recycling process and increases productivity. Operators can use these attachments with 20 to 30-ton excavators, making it easy to adapt to different tasks and equipment.

Shear attachments provide quick and accurate cuts, reducing the time needed for each vehicle.

Strong construction means machines last longer and need fewer repairs, which lowers maintenance costs.

Flexible compatibility with existing equipment helps facilities adjust to changing workloads.

Car balers automate the compression and bundling of vehicles, replacing slow manual work.

These balers can reduce a vehicle’s size by up to 80%, making storage and transport much easier.

Rapid processing means a single vehicle can be handled in minutes, not hours or days.

Compact bales lower transportation and storage costs, which improves overall profitability.

Efficiency improvements let recycling centers handle more vehicles each day, saving time and money.

Safety

Safety remains a top priority in any facility that uses heavy machinery. Car dismantling machines enforce strict safety protocols to protect workers from accidents. Facilities set clear rules and procedures, hold regular safety meetings, and encourage open communication about safety concerns.

Only trained personnel can enter high-risk areas with heavy machinery. Barriers, signs, and access controls keep others out.

Workers must wear personal protective equipment (PPE) such as hard hats, safety glasses, gloves, and high-visibility clothing.

Staff inspect and maintain tools and machines regularly to prevent malfunctions.

Operators secure machines when not in use by lowering blades, locking moving parts, and disabling ignition systems.

Lockout/tagout procedures isolate energy sources during repairs to prevent accidental startup.

Comprehensive safety training teaches workers how to recognize hazards, use PPE correctly, and follow emergency protocols.

These steps help create a safe workplace and reduce the risk of injuries.

Environmental Impact

Mechanized dismantling has a positive effect on the environment. Machines like shears, crushers, and sorting systems improve recycling efficiency and maximize material recovery. This process supports eco-friendly practices by reducing pollution and encouraging the reuse of valuable resources. By using advanced technology, recycling centers can recover more metals and materials from each vehicle, which means less waste ends up in landfills.

Mechanized dismantling also helps prevent environmental pollution. Machines remove hazardous fluids and materials safely, keeping harmful substances out of soil and water. The improved recovery of metals and plastics reduces the need for new raw materials, which conserves natural resources and lowers greenhouse gas emissions.

Mechanized recycling supports a cleaner environment and helps meet strict environmental standards.

Profitability

Car dismantling machines play a key role in making automotive recycling more profitable. These machines help businesses recover more valuable materials from each vehicle. They also lower operating costs and increase the number of cars processed each day.

Ways Car Dismantling Machines Boost Profitability:

Higher Material Recovery: Machines like the Runye Car Dismantling Machine use advanced cutting and sorting tools. These tools help recyclers extract more metals, plastics, and reusable parts. More recovered material means more products to sell.

Reduced Labor Costs: Automation reduces the need for manual labor. Fewer workers are needed to dismantle each car. This change lowers payroll expenses and helps businesses stay competitive.

Faster Processing Times: Modern machines can dismantle vehicles much faster than manual methods. Higher speed means more cars can be processed in a single shift. Increased throughput leads to higher revenue.

Lower Maintenance and Downtime: Well-designed machines require less frequent repairs. Reliable equipment keeps the operation running smoothly. Less downtime means more consistent profits.

Better Organization: Machines help create a more organized workflow. Clear steps and automated processes reduce mistakes. Fewer errors mean less wasted material and higher returns.

Tip: Investing in advanced equipment like the Runye Car Dismantling Machine can pay off quickly. Businesses often see a return on investment within a few years due to increased efficiency and higher material recovery rates.

Here is a table showing how car dismantling machines impact key profit factors:

| Profit Factor | Manual Dismantling | Machine-Assisted Dismantling |

| Material Recovery Rate | Moderate | High |

| Labor Costs | High | Low |

| Processing Speed | Slow | Fast |

| Downtime | Frequent | Rare |

| Revenue per Vehicle | Lower | Higher |

Recycling centers that use advanced machines can also take on larger contracts. They can meet strict industry standards and handle more vehicles from insurance companies, government fleets, and auto dealers.

Profitability does not only come from selling scrap metal. Many dismantling machines help recover reusable parts, electronics, and specialty materials. These items can be sold separately for extra income.

Industry Importance

Sustainability

Sustainability has become a central goal in the automotive recycling industry. Automated dismantling machines now allow direct reuse and refurbishment of undamaged vehicle parts. This process reduces the need for new manufacturing, which saves energy and raw materials. Universal automated disassembly cells can digitize vehicles and extract components without causing damage. These systems help recyclers recover more parts for remanufacturing, supporting a circular economy.

Robotics and artificial intelligence play a key role in improving the purity and quality of recovered materials. Companies use AI-assisted optical systems to sort metals, plastics, and glass with high accuracy. For example, some projects use these technologies to increase the use of recycled materials in new cars. Automated systems also help recover up to 90% of a vehicle’s weight, turning waste into valuable resources. This approach lowers energy use, reduces landfill waste, and supports global sustainability goals.

Automated dismantling supports a cleaner environment by maximizing resource recovery and minimizing waste.

Regulatory Compliance

Strict regulations shape the way automotive recycling operates worldwide. In the European Union, the ELV Directive 2000/53/EC sets high standards for recovery and recycling. Vehicles must reach at least 95% recovery and 85% recycling by weight. Hazardous substances like lead, mercury, and cadmium face strict limits. Dismantling centers must follow proper depollution and material separation procedures.

The United States enforces EPA guidelines for hazardous material handling and recycling, with each state having its own rules for auto salvage.

Japan’s Automobile Recycling Law requires take-back and recycling fees, while India’s Vehicle Scrappage Policy aims to formalize dismantling and cut emissions.

Manufacturers and dismantlers must ensure vehicles are recyclable, provide dismantling information, and work with certified partners.

Proper documentation, such as Certificates of Destruction and material recovery reports, proves compliance.

Equipment used in these facilities must support safe handling of hazardous materials and help meet recycling targets. Machines that enable precise dismantling and material separation make it easier for businesses to follow these regulations.

Market Trends

Several trends influence the adoption of advanced dismantling machines around the world. Environmental regulations have become stricter, pushing companies to invest in better recycling technology. Robotics, artificial intelligence, and machine learning now drive the development of automated systems. These technologies improve efficiency, accuracy, and material recovery rates.

The rise of electric and hybrid vehicles creates new challenges for recyclers. Specialized processes are needed to handle lithium-ion batteries and other unique components. Asia Pacific leads in growth due to high volumes of end-of-life vehicles and strong policies for electric vehicle battery recycling. China stands out as a global leader in electric car markets, shaping the need for new dismantling solutions.

North America and Europe focus on automation and sustainability. Companies in these regions adopt advanced machines to meet environmental standards and manage labor costs. The growing demand for recycled automotive parts and the push for a circular economy encourage further investment in innovative dismantling technologies.

The industry continues to evolve as new vehicle types and stricter regulations drive innovation in recycling processes.

Future Trends

Automation

Automation is transforming the car dismantling industry. New machines use advanced robotics and artificial intelligence to make the process faster and more accurate. AI-powered robots now use computer vision and machine learning to quickly identify valuable car components such as engines, transmissions, and electronics. Robotic arms, equipped with cameras and sensors, can recognize and remove parts with high precision. This technology increases dismantling efficiency and reduces the need for manual labor.

Robots identify and extract valuable materials like metals, plastics, and batteries.

Automation increases speed and reduces human error.

Machines help minimize injury risks for workers.

AI systems manage inventory by cataloging and predicting demand for salvaged parts.

Future car recycling centers will rely on automated machinery and digital systems to maximize efficiency and safety. Specialized facilities will focus on tasks such as battery recycling and metal recovery. These advancements will help improve recycling rates and reduce landfill waste.

Automation supports recycling and reuse efforts, making the industry more sustainable and productive.

Advanced Safety

Safety remains a top priority as technology advances. Modern car dismantling machines now include more safety features than ever before. Designers add enclosed cutting tools and shields to prevent accidental contact. Automated fluid draining systems reduce the risk of spills and exposure to hazardous substances. Emergency stop buttons and clear control panels allow operators to respond quickly to any issues.

New machines also use sensors to monitor operations in real time. These sensors detect unsafe conditions, such as overheating or excessive vibration, and alert workers immediately. Some systems can even shut down the machine automatically if they sense a problem. This proactive approach helps prevent accidents and keeps workers safe.

Advanced safety features protect both workers and the environment, ensuring compliance with strict regulations.

Digital Integration

Digital integration is changing how car dismantling machines operate and how teams monitor them. IoT sensors now track machinery parameters like temperature, vibration, and speed in real time. Data from these sensors helps maintenance teams spot problems early. When a machine shows signs of trouble, teams can fix it before it breaks down. This approach, called predictive maintenance, reduces downtime and keeps operations running smoothly.

IoT sensors provide continuous monitoring of equipment.

Data analysis detects anomalies and schedules repairs only when needed.

Predictive maintenance extends the lifespan of machines.

Digital twin technology simulates real-world conditions, allowing for remote diagnostics and optimized maintenance schedules.

Digital systems also help operators manage workflow and track material recovery rates. By using these technologies, recycling centers can improve efficiency, reduce costs, and ensure that equipment stays in top condition.

Digital integration leads to smarter, safer, and more reliable car dismantling operations.

Car dismantling machines help the automotive industry save resources and protect the environment. These machines recover reusable parts, safely handle hazardous materials, and support local jobs. Advanced equipment like the Runye Car Dismantling Machine increases efficiency and safety while promoting sustainability.

They extend the life of car parts and reduce waste.

New technologies, such as AI, will help recyclers handle complex vehicles and materials in the future.

Car dismantling machines will remain essential as the industry moves toward a circular economy.

FAQ

What is a car dismantling machine?

A car dismantling machine is a specialized tool that breaks down vehicles into parts and materials. It helps recyclers recover metals, plastics, and reusable components quickly and safely.

How does the Runye Car Dismantling Machine improve recycling?

The Runye Car Dismantling Machine uses advanced cutting tools and safety systems. It speeds up the dismantling process and increases the amount of valuable material recovered from each vehicle.

Are car dismantling machines safe for workers?

Modern machines include safety shields, emergency stops, and automated fluid removal. These features protect workers from accidents and hazardous materials.

Safety remains a top priority in automotive recycling facilities.

What materials can recyclers recover with these machines?

Recyclers can recover steel, iron, aluminum, copper, plastics, and glass. Some machines also help separate and collect fluids for safe disposal.

| Material | Common Use |

| Steel | Car bodies |

| Aluminum | Engine parts |

| Copper | Wiring |

| Plastics | Interiors |

Why do recycling centers use automated machines?

Automated machines increase efficiency and reduce manual labor. They help centers process more vehicles each day and improve the quality of recovered materials.

Can one machine handle all types of vehicles?

Most car dismantling machines can process a wide range of vehicles, including cars, SUVs, and light trucks. Some attachments allow for handling larger or specialized vehicles.

How do car dismantling machines help the environment?

These machines recover more materials and reduce landfill waste. They also safely remove hazardous fluids, which prevents pollution and supports sustainability goals.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

አማርኛ

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

עברית

Latine

Dansk

اردو

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Māori